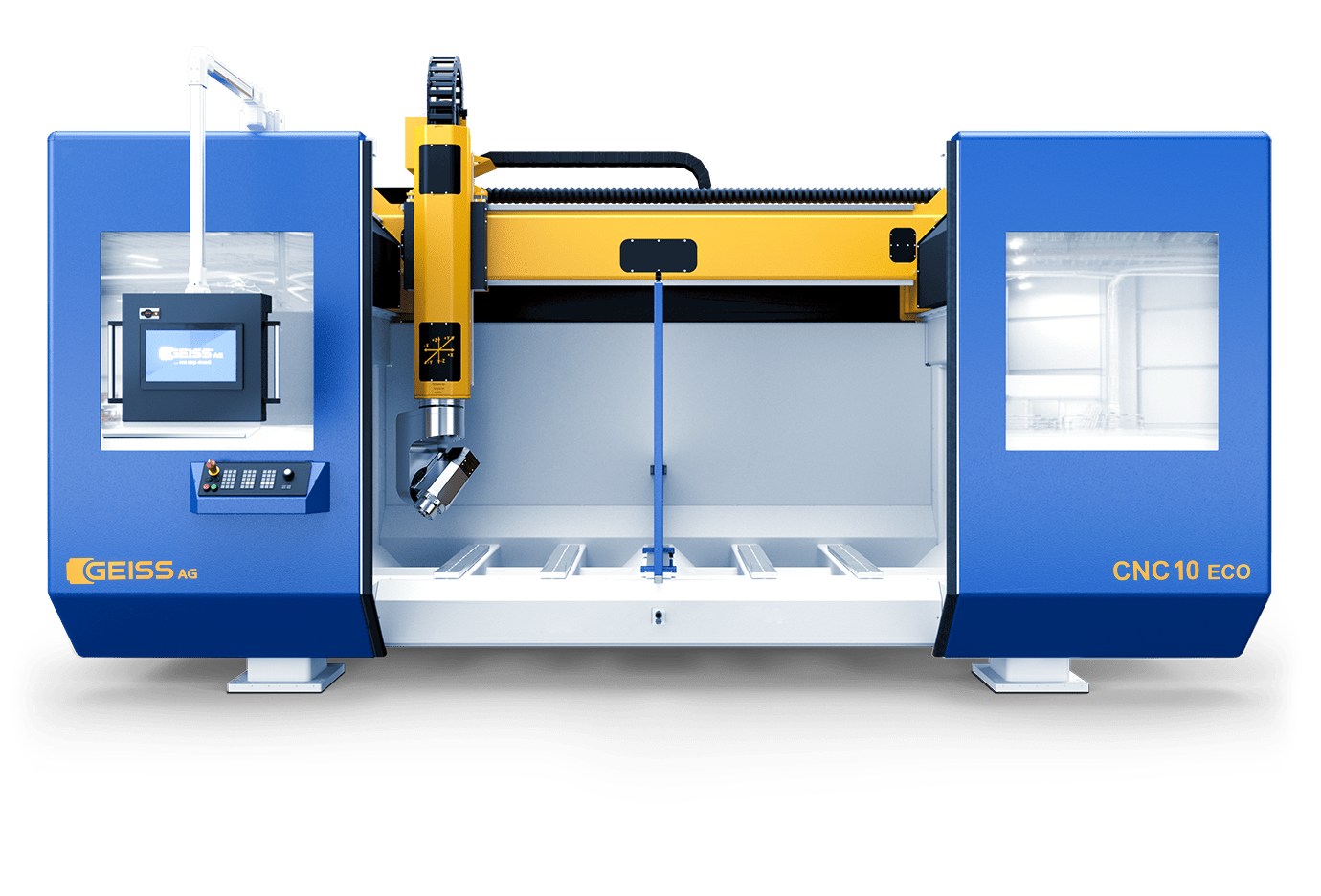

CNC Trimming machine

parametrics

, and proves that innovative design and high functionality go hand in hand.

Features

Unlimited performance

Features

Maximum efficiency,

maximum precision.

Benefits

at a glance

Highest precision in manufacturing

Achieving the highest quality standards in production

Integration of a wide variety of trimming heads

Weight-optimised axle design

Efficient chip extraction concepts

High stiffness of the machine housing and machine axes

Compact machine design

Modernised appearance

Perfect parametric: No more compromises in machine size

Maximum productivity through intelligent automation concepts

Form follows function: Your product determines the machine form

Longevity through high product quality and the use of quality components

Your production,

Your choice.

Whether for plastic machining or for model and tool making, the CNC10 ECO trimming machine from GEISS is tailored specifically to your application requirements.

| For post-processing | For model and tool making | |

|---|---|---|

| Field of application | Contour milling in plastic, composite or aluminum parts | Production of free-form surfaces made of plastic, wood or aluminum |

| Milling heads | Milling heads in different performance levels with optimized component accessibility | Powerful milling heads for toolmaking |

| Drive technology | Ball screws or linear motors | Ball screws or linear motors |

| Optional measuring and control technology | Touch probes, laser measurement, error compensation, direct measuring system in all axes, … | Touch probe, laser measurement, error compensation, direct measuring system in all axes, … |

| Optional machine equipment | Shuttle tables, rotary tables, tool changers, machine hoods, extraction and chip conveyor systems, … | Shuttle tables, rotary tables, tool changers, machine hoods, extraction and chip conveyor systems, … |

Experience CNC top performance

| Standard (ball screws) | Linear motors | |

|---|---|---|

| Speed | Up to 84 m/min | Up to 180 m/min |

| Acceleration | Up to 7 m/s² | Up to 15 m/s² |

| Machine sizes | From 1000 x 600 x 310 mm | From 1000 x 600 x 310 mm |

| Travel distances | Maximum 6 m | Up to 32 m |

| Milling spindles | Various options available | Various options available |

Your title

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Machine bed with fixed machine table as a stable foundation

Portal for the trimming head with X-, Y- and Z-axis

Trimming head with high-frequency spindle for precise trimming processes

SINUMERIK One: The latest and most powerful CNC control from Siemens for movements and trimming programmes

Control panel with touchscreen display and keypad

Machine control panel

Vacuum equipment with vacuum pump, vacuum valve and release valve

Clamping system for secure fixation of the workpiece

Protective covers for operator protection during the trimming process

Cooling system for tool and workpiece cooling

Lubrication system to reduce friction and wear on machine components

Your title

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Trimming heads and trimming spindles for a wide range of challenges

Linear motors

Other processing methods such as ultrasonic cutting, cold knife cutting or laser cutting

Additional vertical axes

Automatic tool changing systems

Sideshuttle, front shuttle or rotary tables for ergonomic loading of the machine

Machine enclosure

Partition for dual-station operation

Chip and dust disposal systems

Alternative vacuum equipment for workpiece clamping

Measuring devices for various measurement and calibration tasks

Software options for additional control functions

Options for data acquisition and data logging

and much more.

Maximizing your production efficiency

We accompany you in your project from start to finish. Once you present your product to us, we work closely with you to identify the specific requirements for the CNC trimming machine and to find the appropriate equipment. Every step is focused on quality and precision to ensure that your end product meets the highest standards.

The planning phase concludes with the design of a prototype tool. Upon your approval, we manufacture your specially customized trimming machine. Our experts are by your side throughout the entire process to ensure the success of your project and provide you with first-class service.

HMI software SINUMERIK Operate

SINUMERIK ONE control system

, which is integrated into our machines, sets new standards in performance and efficiency. With 30% increased NCK performance and innovative Safety Integrated Plus technology, maximum safety and ease of operation are guaranteed. Supplemented by modern operating components such as the 19″ widescreen TFT touch display and the extensive programming options, it stands for advanced precision and flexibility in CNC machining.

Downloads

Contact person

We are there for you. Everywhere. If you have any questions or need support, you can use our contact tool to get in touch directly with experts in your area to find customised solutions and clarify any unanswered questions.

You might also be interested in

Precision down to the last detail

With GEISS trimming jigs, you can trim your thermoformed parts to the perfect shape. Take advantage of our many years of experience and state-of-the-art technologies for your customised solutions.

Your GEISS