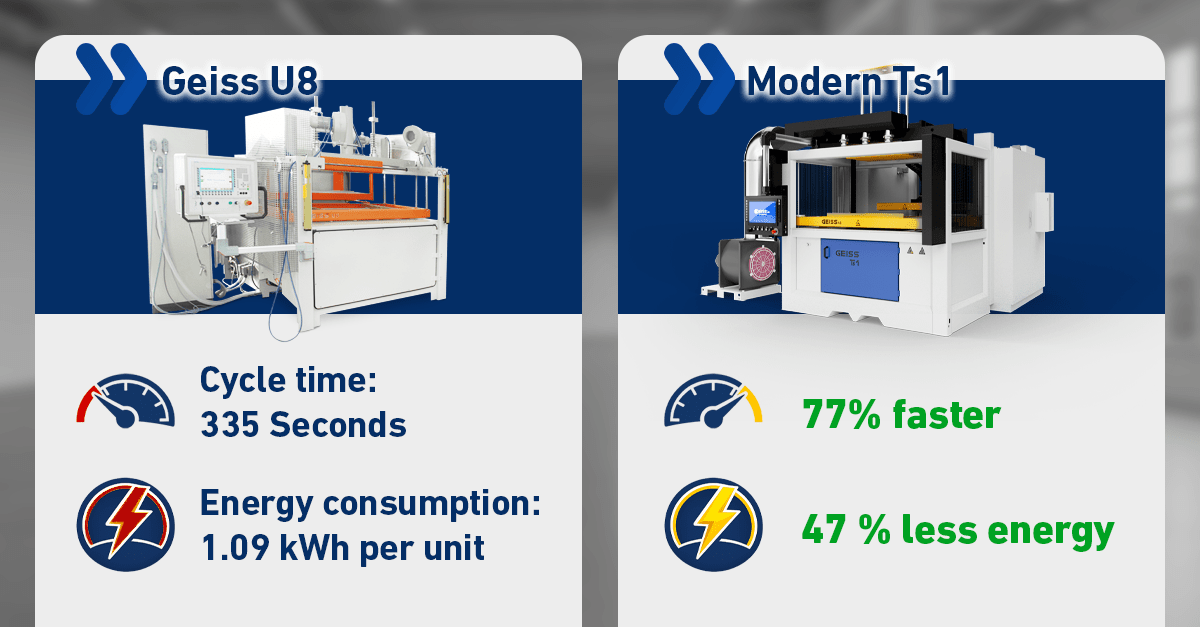

Technological progress in numbers

For a component made of PC ABS, our new T11 machine was evaluated under series production conditions in a direct comparison with a T8 thermoforming machine.

The results show a clear performance improvement in key production metrics. Both the cycle time and the energy consumption per component were significantly reduced.

The T11 therefore achieves significantly higher productivity while at the same time delivering a clearly improved level of energy efficiency.

| U8 thermoforming machine | T11 thermoforming machine | |

|---|---|---|

| Cycling times | 335 seconds | 75 seconds |

| Time savings | 72 hours for 1000 parts | |

| Power consumption | 1,09 kWh per part | 0,58 kWh per part |

| Power savings | 510 kWh for 1000 parts |

The analysis shows a significant improvement in the key performance indicators.

The cycle time is reduced by 77 percent. At the same time, more than four times as many parts are produced in the same amount of time, while the energy consumption per component decreases by 47 percent.

The increase in efficiency is based on advanced machine drives, the precise control system from Geiss, and modern high performance heating elements.

The optimized interaction of these components accelerates the process and increases energy efficiency.

Contact person

We are there for you. Everywhere. If you have any questions or need support, you can use our contact tool to get in touch directly with experts in your area to find customised solutions and clarify any unanswered questions.

Your GEISS